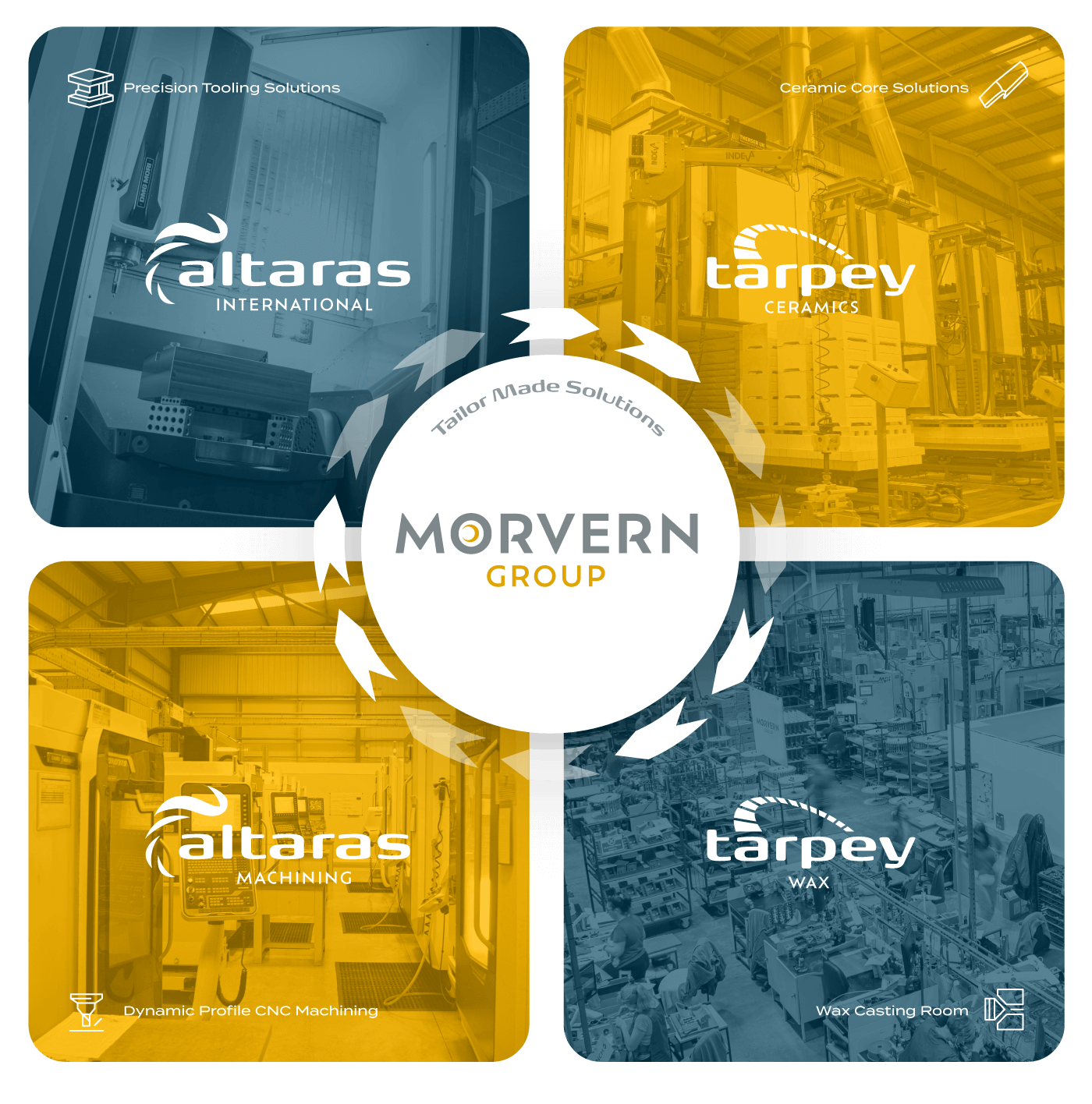

Morvern Group is dedicated to delivering innovative solutions for our customers. With deep expertise in tooling, ceramic cores, wax injection and assembly, and precision machining, we specialize in turbine airfoil products, serving aerospace and industrial gas turbine OEMs and Tier 1 suppliers. Our experience and resources empower us to meet the evolving demands of our clients.

Morvern Group is shaping the future of investment casting by delivering unmatched value, innovation and fostering a culture of excellence.

Lasting and rewarding relationships are key to our approach. Together with our customers, we deliver the future. We go beyond expectations.

Scroll right

Integrated solution provider for investment cast turbine airfoils

Offering precision tooling solutions for the investment casting industry specialising in turbine airfoils for the aerospace and industrial gas turbine markets.

Find Out More

Specialising in the worlds most cutting edge materials for turbine airfoil cores used in aerospace and industrial gas turbine components.

Find Out More

A fully capable wax room with highly skilled technicians to service investment casting foundries specialising in aerospace engine and industrial gas turbine components.

Find Out More

Servicing the turbine supply chain with expertise in expertise in machining turbine airfoil investment castings for the aerospace engine and industrial gas turbine sectors.

Find Out MoreMorvern Group is shaping the future of investment casting by delivering unmatched value, innovation and fostering a culture of excellence.

Lasting and rewarding relationships are key to our approach.

Together with our customers, we deliver the future.

We go beyond expectations.

Focused on complex turbine airfoils for the aerospace and industrial gas turbine applications

Industry leading leadtimes are achieved using the newest design, 5-axis CNC and digital EDM equipment and methods

Experienced and skilled in concurrent design and component development for today's most efficient turbines

Multiple redundant capabilities and skills allow for concurrent projects to be delivered on time to quality standards

Optimised process for complex turbine airfoils ranging from small aerospace to large IGT cores

Newest ceramic core body in the market

Our products are demanded by our customers for use in the most complex turbine airfoil components

Services that range from prototype and small batch runs to extended workbench and annual production requirements

Dedicated to turbine airfoils and associated components

Injection, inspection, preparation and ready to dip mold assemblies. Proven techniques to transport patterns globally

Return casting to nominal profile with 5-Axis CNC

Pioneered the removal of trailing edge encapsulation using traditional CNC methods to reduce operator scrap

Dedicated to meeting the lead time demands of our customers and investing to meet increasing volumes